Mold fabrication is a crucial upstream process enabling efficient mass production of intricate cast metal components through die casting. As a renowned mold manufacturing specialist, Junying offers comprehensive mold making solutions tailored to clients' die casting needs. This article explores the methodology, advantages, applications and Junying's expertise in delivering high-quality molds.

Die Casting Mold Design and Materials

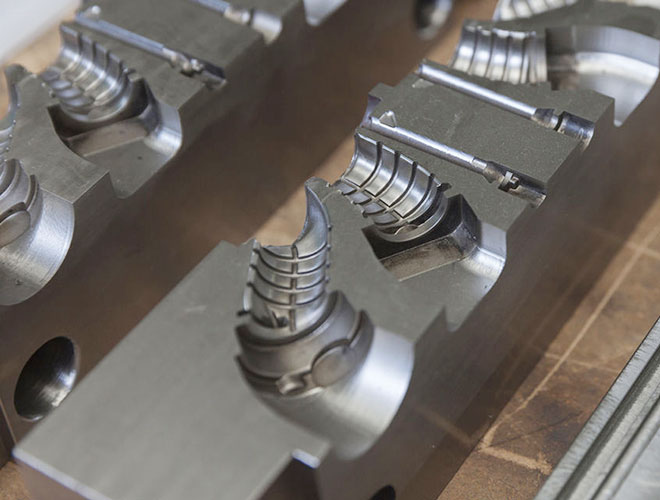

An ideal mold consists of movable and stationary steel blocks machined to precise cavity and core details. Design aspects encompass draft angles, ejector placements, feedings and vents to facilitate part extraction and molten metal flow.

Commonly used mold steel grades at Junying include H13, D2 and P20 that amalgamate attributes like hardness, wear-resistance and polishability for operational longevity. Premium grades like AISI H11 and H13MoCo improve mold life further for high-volume production.

Mold Manufacturing Process

Key activities involve computer-aided design of cavities and cores, precision CNC milling/turning, electrical discharge machining of complex shapes, surface grinding and polishing.

For complex molds, modular mold designs enable economical repairs. Stress-relieving heat treatments prevent cracking during cyclic loading. Guide bushings aid free sliding motion minimizing parting line marks.

Mold Making Services at Junying

Leveraging two decades expertise, Junying owns latest 5-axis machining centers, wire-cut EDM machines and automated grinding/polishing cells. In-house Heat Treatment department aids metallurgical consistency.

Experienced toolmakers aid rapid prototyping through concurrent engineering principles. Production molds withstand 500,000 cycles assuring consistent output quality for OEMs.

As an integrated provider, Junying facilitates project timelines through value-added die casting, finishing and assembly capabilities from a centralized facility.

Advantages of Precision Mold Making

Attributes that enhance manufacturing productivity and cost-effectiveness include:

-

Dimensional stability for maintaining close tolerances over lifecycles

-

Minimal repairs and downtime through proven designs and quality steels

-

Simultaneous multi-cavity designs improve output rates

-

Smooth polished surfaces enhance cast part quality

-

Modular mold repairs reduce reconstruction lead times

Applications across Industries

Die casting molds serve critical needs in automotive, consumer durables, electronics, hardware through:

-

Automotive subsystem fabrication

-

Appliance housing components

-

Connectors and small electromechanical devices

-

Architectural fittings requiring metallic sheen and durability

-

Medical device housings for hygienic smooth finishes

Service Capabilities at Junying

From conceptual design through commissioning and production support, Junying caters the entire mold lifecycle:

-

Design consultation, development and validation support

-

CNC machining, EDM, heat treatment and finishing

-

Automated transfer systems for robotic tending

-

Qualification documentation generation

-

Online technical advisory and field maintenance

-

Inventory management for on-demand repairs

In summary, precision mold making plays a defining role in high-volume manufacturing viability. As a competent one-stop solution provider, Junying consistently delivers production quality tools serving clients' casting production needs.