Revolutionizing Precision: How Mart Laser Redefines Laser Machine Design for Industrial Excellence

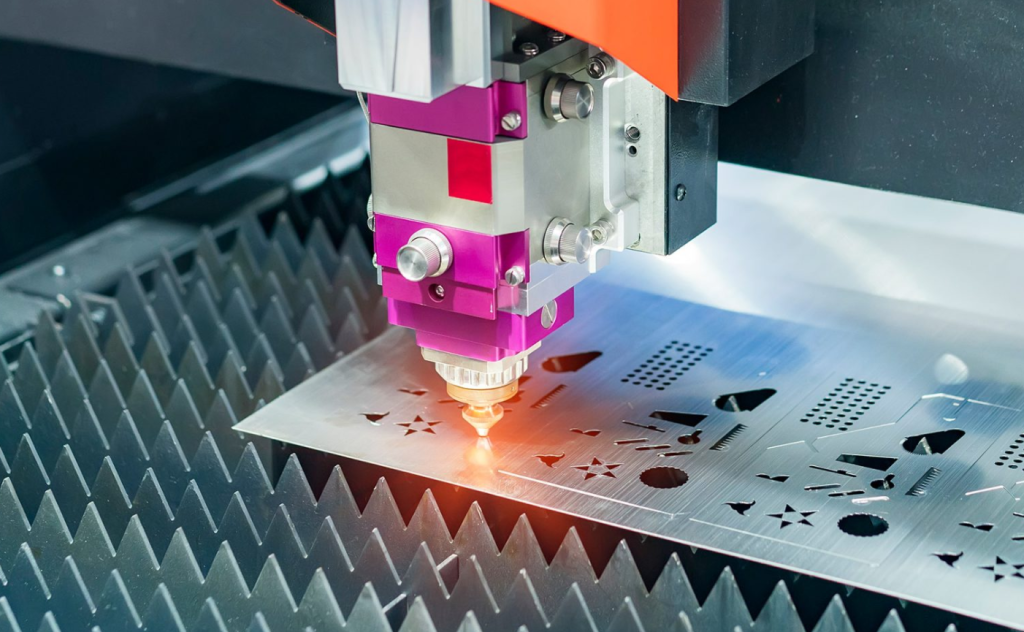

Laser machine design plays a pivotal role in shaping industries that rely on precise material cutting, engraving, and marking. From automotive components to intricate jewelry patterns, the design and build of a laser machine directly influence performance, accuracy, and efficiency. Mart Laser, a recognized name in the industrial laser sector, delivers innovation-driven solutions engineered for modern manufacturing challenges.

With years of field expertise, Mart Laser focuses on durable hardware, intuitive software integration, and user-centric engineering. Let's dive deep into what makes Mart Laser a trusted player in laser machine design.

Why Laser Machine Design Matters

Before understanding how Mart Laser optimizes its machines, here’s why design is at the heart of any laser technology:

| Design Element | Impact on Performance |

|---|---|

| Beam Delivery System | Ensures accurate energy transfer to the target material |

| Cooling Mechanism | Prevents overheating, enhances lifespan |

| Control Interface | Influences user accessibility and operational smoothness |

| Motion System | Affects precision, speed, and edge quality |

| Structural Stability | Reduces vibration, improves cutting accuracy |

Key takeaway: Poor design results in downtime, wastage, and inconsistent output.

Mart Laser’s Approach to Design Excellence

Mart Laser’s engineering philosophy centers on precision, durability, and adaptability. Their machines undergo rigorous R&D cycles, ensuring compatibility with real-world industrial conditions.

Key Design Highlights:

-

Industrial-Grade Frames: Reinforced steel body resists thermal distortion and maintains alignment across long operational hours.

-

Modular Components: Easily replaceable optics, mirrors, and lenses help reduce maintenance downtime.

-

High-Speed Galvo Heads: Built for high-resolution marking with unmatched repeatability.

-

Closed-Loop Control Systems: Adaptive response to feedback for enhanced control and fine-tuning.

-

User-Friendly Interfaces: Touch-screen controls and smart diagnostics for ease of use.

Industries Benefiting from Mart Laser Designs

Mart Laser machines serve a wide array of sectors:

-

Metal Fabrication – Precision cutting for steel, aluminum, and titanium.

-

Electronics – Micron-level engraving on PCBs and chips.

-

Jewelry – Intricate, high-detail laser marking without heat damage.

-

Medical Devices – Clean and burr-free surgical tool cutting.

-

Automotive – Parts engraving, VIN coding, and welding.

How Mart Laser Ensures EEAT Compliance

Expertise

Mart Laser employs engineers with over a decade of specialization in photonics, CNC integration, and optics. Their design team is involved in international technical expos and peer-reviewed studies in laser technology.

Experience

Mart Laser has implemented custom machine designs for over 1,000+ clients globally, adapting to diverse industrial requirements from small workshops to large-scale OEMs.

Authoritativeness

Mart Laser's research-backed designs are cited in technical white papers and adopted by global manufacturing leaders.

Trustworthiness

All machines go through multi-stage quality assurance protocols, including thermal resistance testing, calibration audits, and ISO-certified documentation.

Real-World Performance Metrics

| Specification | Mart Laser Typical Value |

|---|---|

| Positioning Accuracy | ±0.01 mm |

| Repeatability | ≤0.005 mm |

| Laser Power Range | 20W - 2000W (depending on model) |

| Lifespan (Laser Source) | 100,000 hours (average tested) |

| Cooling Options | Air-cooled & Water-cooled |

FAQs: Laser Machine Design by Mart Laser

Q1: What software systems are compatible with Mart Laser machines?

Mart Laser machines support industry-standard platforms including LightBurn, EZCAD, and custom SDKs for seamless integration with factory systems.

Q2: Can Mart Laser machines handle multi-material operations?

Yes, their hybrid laser models are designed to process metals, plastics, and ceramics with material-specific settings for optimized output.

Q3: How does Mart Laser handle after-sales design upgrades?

Mart Laser offers firmware upgrades and hardware retrofitting options, allowing customers to evolve their machine's design without full replacement.

Q4: What safety standards does Mart Laser adhere to in machine design?

All designs follow CE and FDA guidelines, incorporating safety enclosures, emergency stop functions, and light barrier sensors.

Key Features That Enhance Visibility and Engagement

-

Quick Setup Guides: Machine packages include intuitive manuals and calibration tools.

-

Training Support: On-site and online operator training available for better productivity.

-

Custom-Built Options: Fully customizable gantry systems, laser source choices (fiber, CO2, UV).

-

Scalability: Designs that accommodate factory-scale expansion with plug-and-play modules.

Final Thought

When precision, reliability, and customization intersect, Mart Laser stands out with its engineered-for-performance laser machine designs. Each unit is a product of thoughtful design, rigorous testing, and industry-specific experience—resulting in machines that adapt to evolving production needs without compromising on quality.